Downloadable Checklist

Fire Sprinkler Inspection and Sprinkler Head Testing

Annual Fire Sprinkler Inspection NFPA 25 5.2

Take this checklist with you or share with your colleagues. With years of experience and hundreds of business served, Brothers Fire & Security can manage all the required inspections on these lists.

Fill out the form to get this checklist sent to your email.

Download Now!

A requirement of NFPA 25, 14.2 (the standard for fire sprinkler inspections) is that every year you are also required to have a licensed contractor conduct an annual inspection of your fire sprinkler system.

This test inspection covers the following:

- Sprinklers will be inspected from the floor level for proper coverage and condition.

- Sprinkler Pipe, Fittings, Hangers, Braces and Supports will be inspected from the floor level for condition.

- Hydraulic Design Information shall be inspected to verify that it is provided, attached to the riser and is legible.

- All Water Flow and Water Control Devices and Valves will be tested.

- Anti-Freeze System Solutions (where applicable) Shall be tested.

Sprinkler Head Testing NFPA 25, 5.3

This test inspection covers the following:

A requirement of NFPA 25, 5.3 is that Fire Sprinkler Heads shall be tested and maintained as follows:

- Sprinkler Heads manufactured prior to 1920 be replaced.

- Sprinkler Heads at 50 years shall be sampled tested, and then every 10 years after that.

- If a head fails this test, then all similar heads shall be replaced.

- Test should consist of 1% of the sprinkler heads with a minimum of 4 heads.

- Sprinkler Heads at 75 years shall be sampled tested, and then every 5 years after that.

- If a head fails this test, then all similar heads shall be replaced.

- Test should consist of 1% of the sprinkler heads with a minimum of 4 heads.

- Dry Sprinkler Heads at 10 years shall be sample tested and then every 10 years after that.

- If a head fails this test, then all similar heads shall be replaced.

- Test should consist of 1% of the sprinkler heads with a minimum of 4 heads.

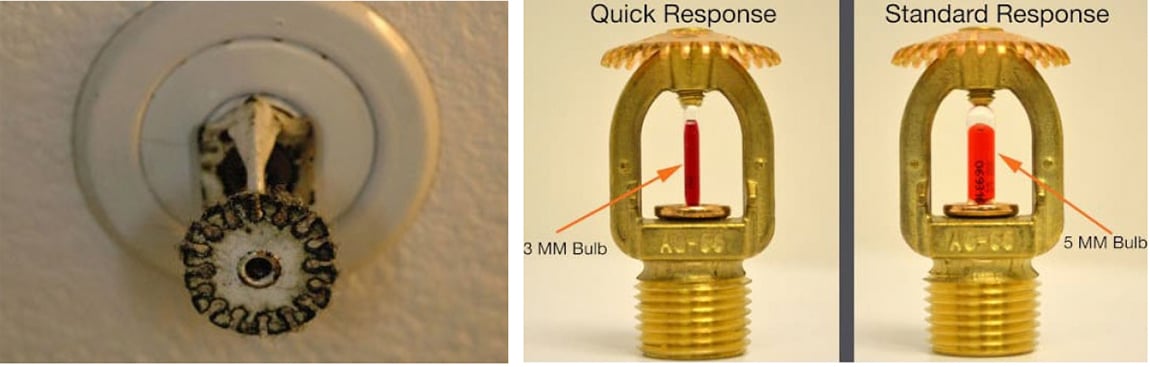

- Quick Response Sprinkler Heads QR at 20 years shall be sample tested and then every 10 years after that.

- If a head fails this test, then all similar heads shall be replaced.

- Test should consist of 1% of the sprinkler heads with a minimum of 4 heads.

- Sprinkler heads in harsh or corrosive environments or high temperature solder link heads (325 degree or higher) shall be sample tested every 5 years and then every 5 years after that.

- If a head fails this test, then all similar heads shall be replaced.

- Test should consist of 1% of the sprinkler heads with a minimum of 4 heads.

Brothers Fire & Security can provide you all necessary labor and materials to perform this inspection for you.

Call 763-441-2290 to speak to one of our sales reps today.

|

Sales Estimating Design Installation |

Inspections Fire Alarm Monitoring Security |

24 Hour Emergency Service & Repair Fire Sprinkler & Suppression Systems |